What is an Asphalt/Composite Shingle?

Composition shingles, also known as composite or asphalt shingles, are a type of roofing shingle made from a combination of materials. The term “composition” comes from the fact that the shingles are made from more than one material, such as asphalt, fiberglass, tar, and granules, rather than just one like wood or clay.

The standard makeup of an asphalt shingle, the most common roofing material in North America, consists of three main components:

- Fiberglass mat: A strong, reinforcing material that’s the backbone of the shingle.

- Asphalt: A water-resistant ingredient that coats the fiberglass fibers and holds the granules in place. Asphalt is also processed to be more resistant to fire hazards.

- Granules: The most visible part of the shingle, granules are crushed and screened to exact size. Granules can come in many colors and provide an aesthetic quality to your roof.

-

- The granules help with installation by providing a surface for roofers to walk on. Additionally, the granules prevent shingles from sticking together.

- The inclusion of granules improves the durability of the shingle.

- The granules help prevent your shingles from ultraviolet rays.

-

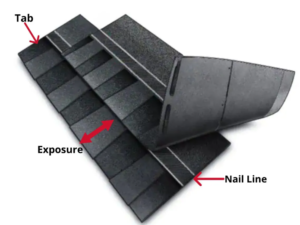

The parts of a Asphalt/Composite Shingle:

Tab: The tabs are the lower sections of the shingles that are exposed to the elements, which slits between them to make them look like individual parts of the shingle when installed. Some shingles have just one tab and others can have up to three tabs.

Exposure: The exposure explains how much of the shingle will show after installation. It simply refers to the exposed area of the shingle, which can also be called the “butt.”

Nail line: The nail line is the tar-lined area of the shingle through which the installer drives the nails. Sticking to this line allows all of the fasteners to be hidden from view (and protected from the weather) once installed.

Alignment Guides.Most shingles include 1/2-in. alignment slits across the top edge and half-slots along the edges. Use these to line up adjacent shingles and successive courses. In addition, shadow marks may run the length of each shingle near the top of the slots.

Types of Ashpahlt/Compostion Shingle:

Dimensional shingles, also known as architectural or laminated shingles-They are made up of multiple layers of asphalt-coated fiberglass that are laminated together, giving them their dimensional appearance. These are the most common type of shingle used today.

Designer/Luxury Shingle-are a high-end type of asphalt shingle that are designed to look like more expensive roofing materials. They are typically thicker and heavier than standard shingles, and can come in a variety of colors, patterns, and textures. Designer shingles are often made to mimic the look of natural materials like slate, cedar, or clay tiles, but with the benefits of asphalt. They can also have added features like impact resistance, algae resistance, or energy efficiency. The

Rubbarized Asphalt Shingle:

Combining high-grade asphalt with virgin rubber polymers, and recycled rubber and plastic polymers, our proprietary NEX® Polymer Modified (Rubberized) Asphalt technology chemically strengthens and rubberizes the asphalt core of the shingle for superior all-weather resilience and longer product life, all while reducing landfill waste.

Strip shingles, also known as 3-tab shingles, are a type of asphalt shingle that are flat and have a single tab size and shape. They are made from a single layer of asphalt and have a slate-like appearance. Strip shingles are the most basic and original type of asphalt shingle and were the most common roofing shingle before dimensional shingles were introduced in the 1980s. These shingles are being coming more and more uncommon.

T-lock shingles are a type of asphalt roofing shingle that were popular from the 1930s to the 1980s. They have a T-shaped design that allows them to interlock with each other, making them more resistant to wind damage than other types of shingles. T-lock shingles were often used in areas with high winds, such as Colorado, Wyoming, and New Mexico. They were also thicker and stronger than other asphalt shingles, and required less maintenance. However, manufacturers began to use less asphalt in T-lock shingles over time, making them thinner and more fragile. T-lock shingles were discontinued in the mid-2000s and are no longer manufactured, so repairing them is not possible. If a T-lock roof is damaged, the entire roof will need to be replaced.

| WHAT ARE THE MAJOR SHINGLE BRANDS? | ||

| Atlas | Dimensional/Designer | https://www.atlasroofing.com/ |

| Certainteed | Dimensional/Designer | https://www.certainteed.com/ |

| GAF | Dimensional/Designer | https://www.gaf.com/ |

| IKO | Dimensional/Designer | https://www.iko.com/ |

| Malarky | Dimensional/Designer/Rubbarized | https://www.malarkeyroofing.com/ |

| Owens Corning | Dimensional/Designer | https://www.owenscorning.com/ |

| Tamko | Dimensional/Designer | https://www.tamko.com/ |

This video shows how asphalt shingles are manufactured. They all start with a core/base sheet (This can be numerous types of product from paper, wood, cloth, or Fiberglass like GAF Timberline HDZ shingles) It comes on a vary large roll. This is sandwiched by a special asphalt/tar. While it is still hot larger granules are layered on the top side, while fine granules are layered on the bottom side. There are numerous styles of shingles (3-Tab as shown in the video, dimensional, and designer styles)