About Lesson

| The GAF Shingle |

| GAF asphalt roof shingles are made using a multi-layered process that includes: |

| Laminating: Multiple layers of engineered asphalt are laminated around a fiberglass core. |

| Applying a coating: A hot mixture of crushed limestone and asphalt is applied to the fiberglass sheets. |

| Adding granules: Ceramic-coated granules are applied to the top of each shingle for protection from UV rays and to achieve the desired color. |

| Cutting: The web is cut into eight different shapes. |

| Combining: The shapes are combined into boards. |

| Packaging: The finished shingles are packaged and ready to be loaded onto a truck |

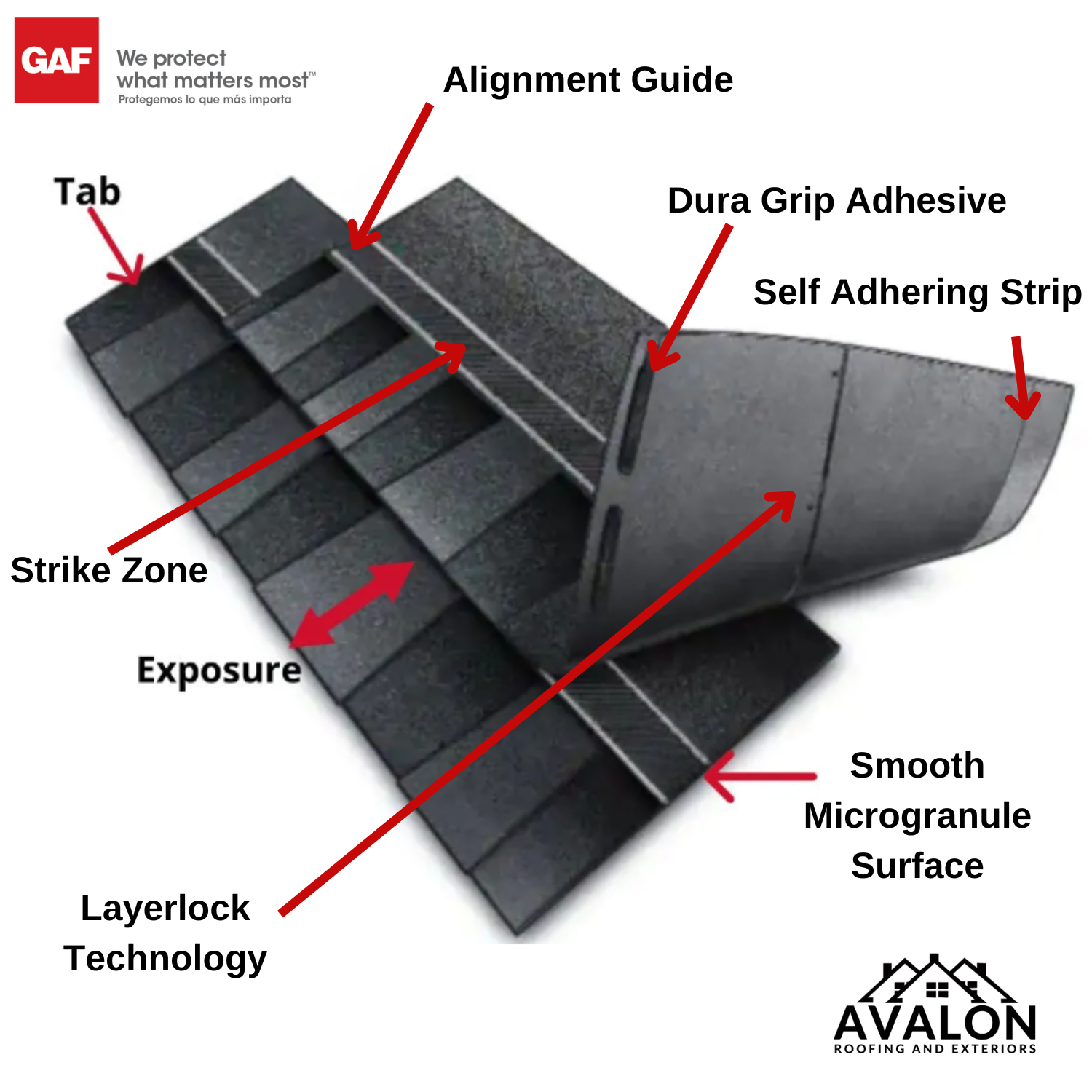

| The anatomy of a GAF Shingle |

| ALIGNMENT GUIDE: GAF shingles are designed with a white chalk guideline, which is used as a guide for the next row of shingles. The exposed area of the shingles below should be 5 ⅝”. This ensures appropriate coverage, adhesion and water-tightness. Make sure the bottom of the pre-cut shingle is flush with the white chalk line. |

| DURAGRIP ADHESIVE: Dura Grip™ Adhesive helps createa strong protective bond on all GAFShingles. But that’s not all. When it’scombined with our patented LayerLock™ Technology, it pairs with the smooth microgranule surface of the StrikeZone™nailing area for a fast tack. The two innovative technologies work together to create a bond so strong that GAF was able to introduce the industry’s first wind warranty with no maximum wind speed limitation |

| https://documents.gaf.com/data-sheets/dura-grip-windproven-technology-resgn751-_data-sheet.pdf |

| SMOOTH MICROGRANULE SURFACE: |

| LAYER LOCK TECHNOLOGY: mechanically fuses the common bond between overlapping shingle layers. |

| https://documents.gaf.com/data-sheets/layerlock-technology-restz114-(4-23)-_data-sheet.pdf |

| EXPOSURE: The visible portion of the shingle. |

|

STRIKE ZONE:The GAF StrikeZone shingle nailing area, engineered LayerLock® Technology, is so easy to hit it gives a roofer 99% nailing accuracy. Find out more today!

|

| TAB: he tabs are the lower sections of the shingles that are exposed to the elements, which slits between them to make them look like individual parts of the shingle when installed. |

Join the conversation